UL Listed

We ensure that our products are both safe and effective. That’s why the ENFusion Blender 2500 is UL Listed.

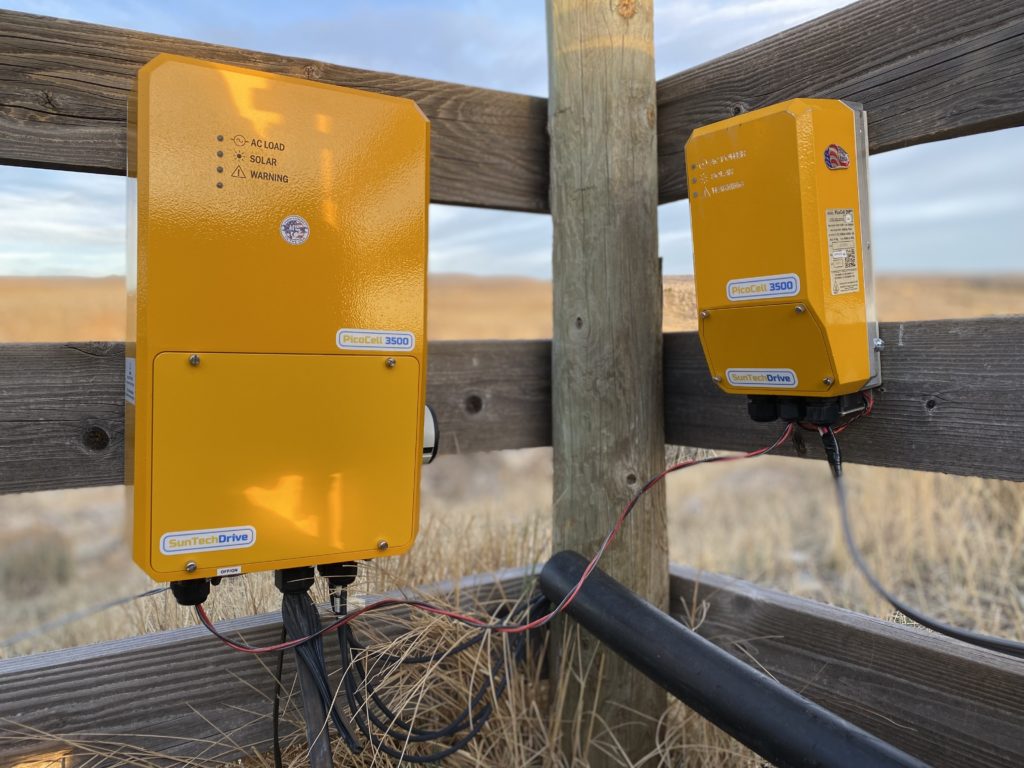

Weatherproof

Clean energy doesn't mean comfortable environments. We've built all of our products with durable enclosures, meaning they can provide you with power, even in the harshest conditions.

Patented

The unique blending technology that drives our innovation is also what sets us apart from the rest.

Made in the USA

Designed and built in Colorado, you can rely on ENFusion™'s products to withstand even the toughest conditions.